Where are Fuel Cells used?

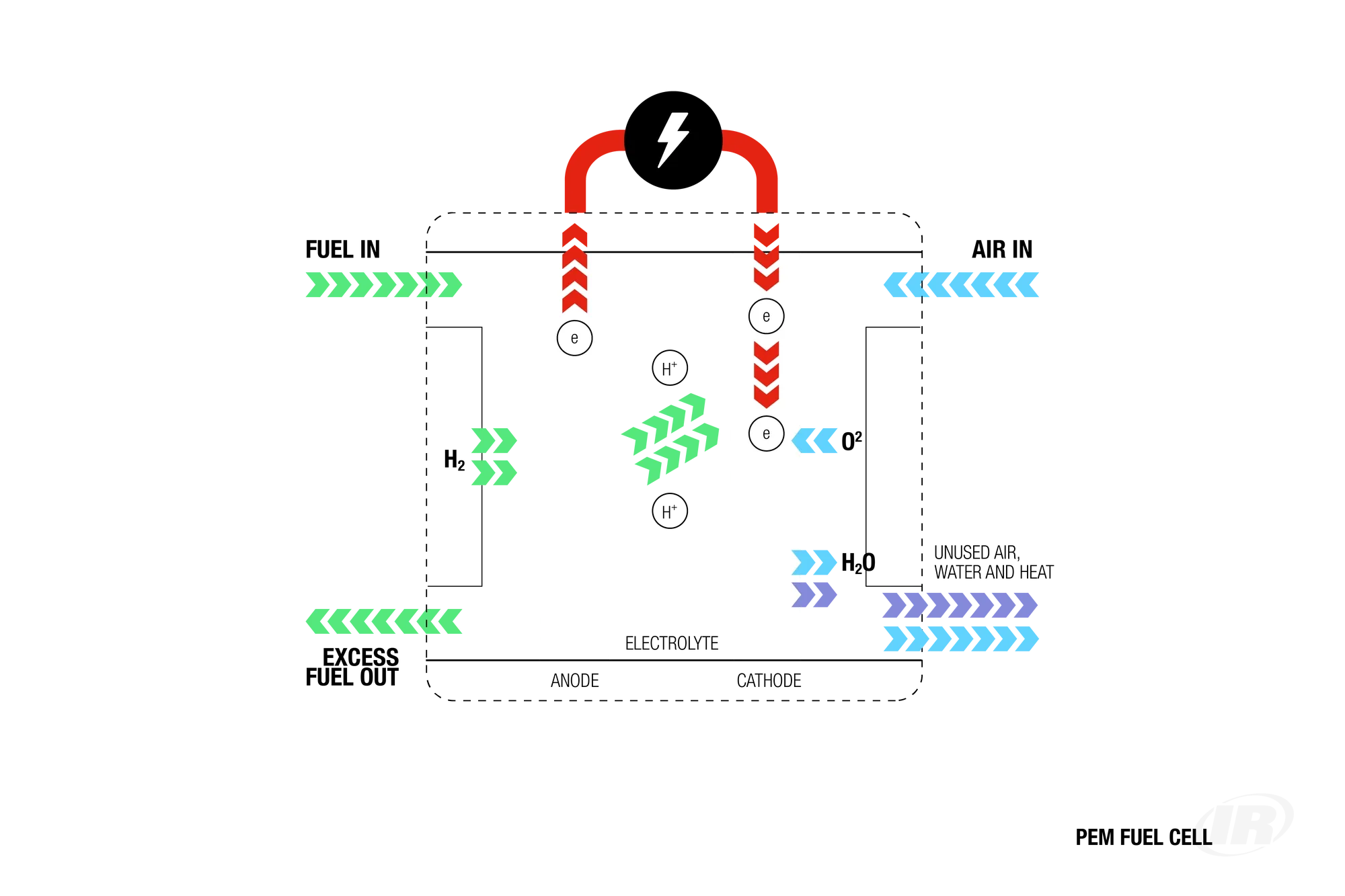

Fuel Cell technologies have a wide variety of applications and are considered an alternative, sustainable and green solution to oil dependency. For example hydrogen fuel cells store hydrogen and oxygen, a chemical reaction between the two elements generates energy and the only byproduct is water. Fuel cells generate no pollution as the only waste they produce is water.

Fuel cells can be used in transport applications to feed buses for city and regional transport but can also be used in hydrogen fuelled marine transportation. Other applications also include forklift trucks, wheel chairs, bikes, small vehicles and light traction. Last, but not least, Fuel Cells are used in stationary applications to generate residential and industrial energy supply.

How are blowers and low pressure compressors equipment used in the fuel cell process?

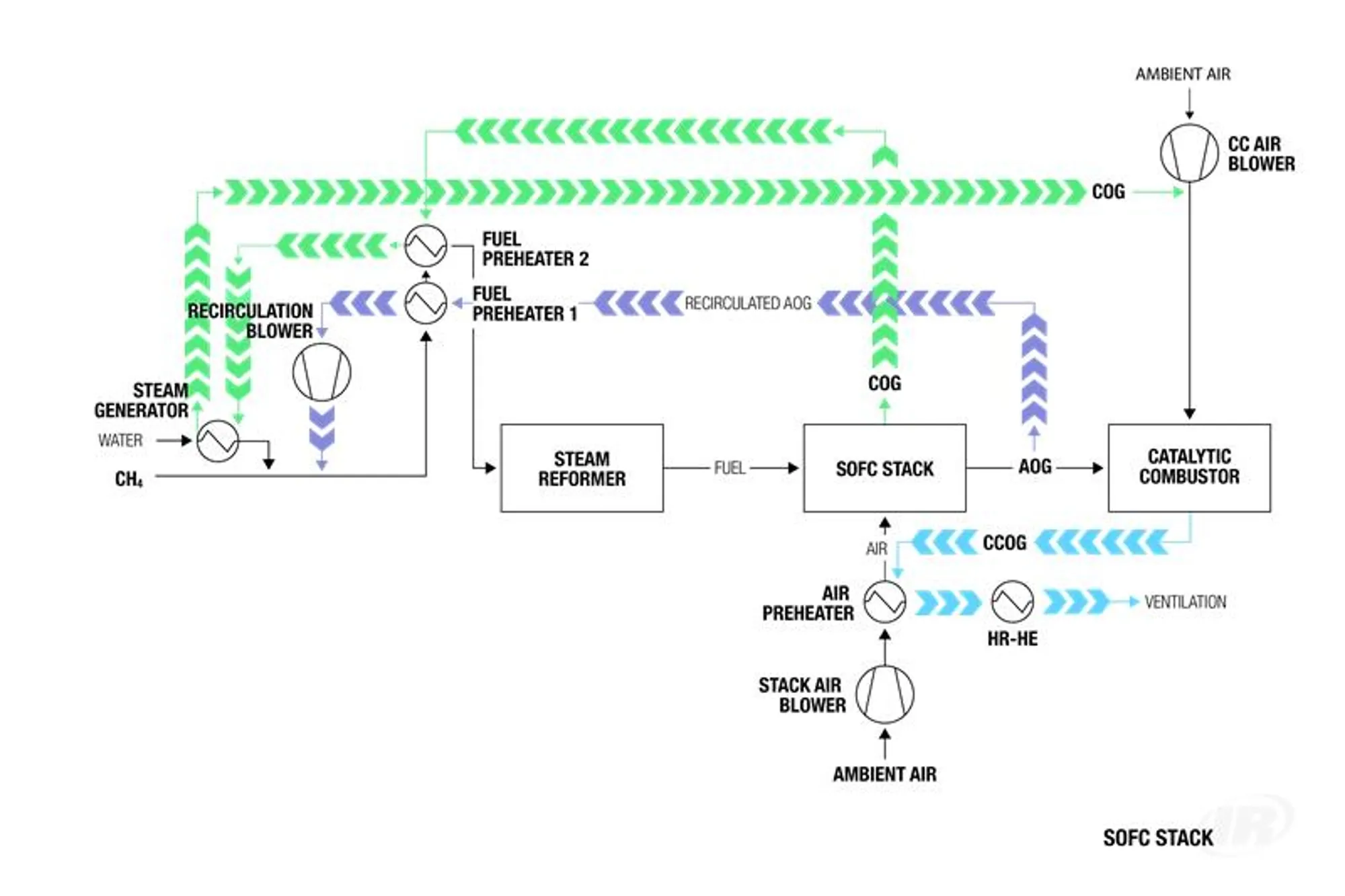

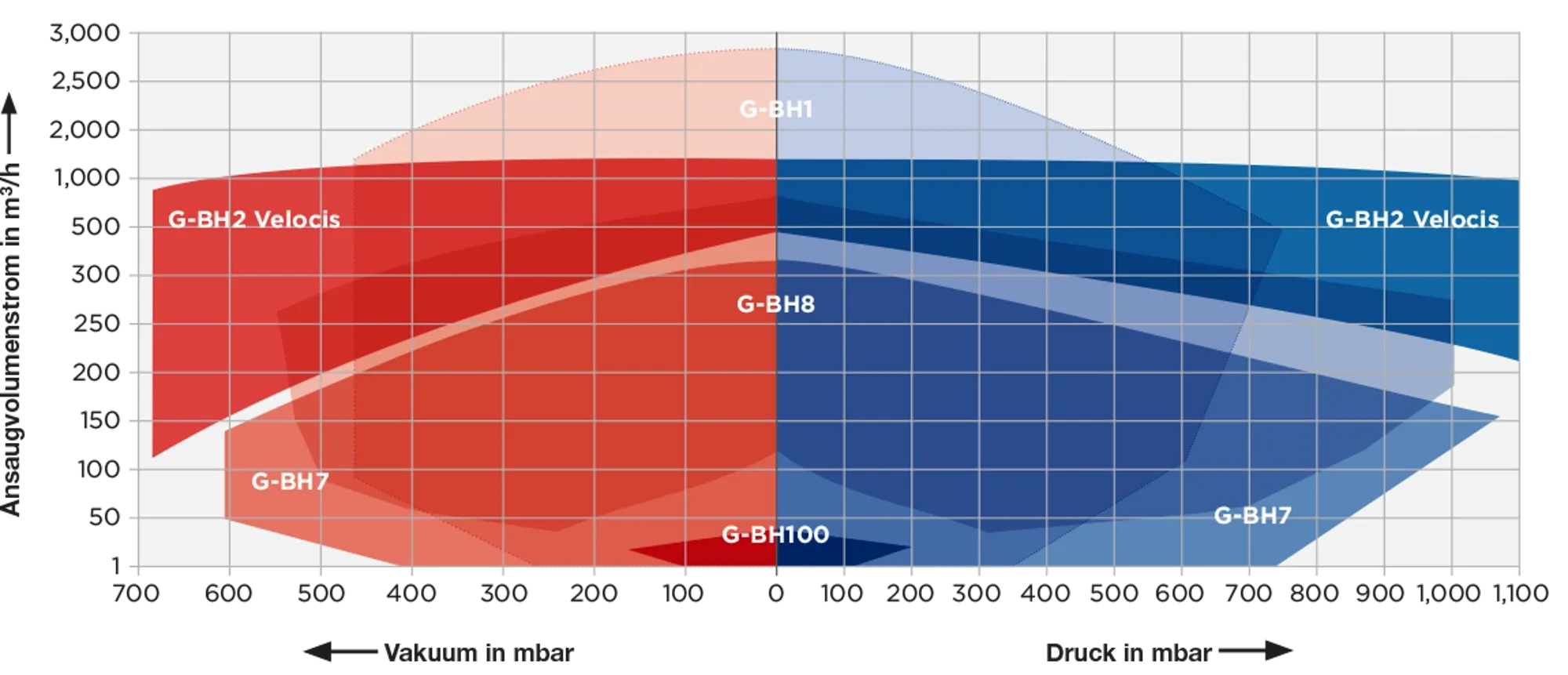

The efficiency of a fuel cell system hinges on its ability to maximize performance while minimizing costs. Blowers and low-pressure compressors play a pivotal role in this equation, as they are responsible for the precise movement of air and gases throughout the system, directly influencing overall efficiency.

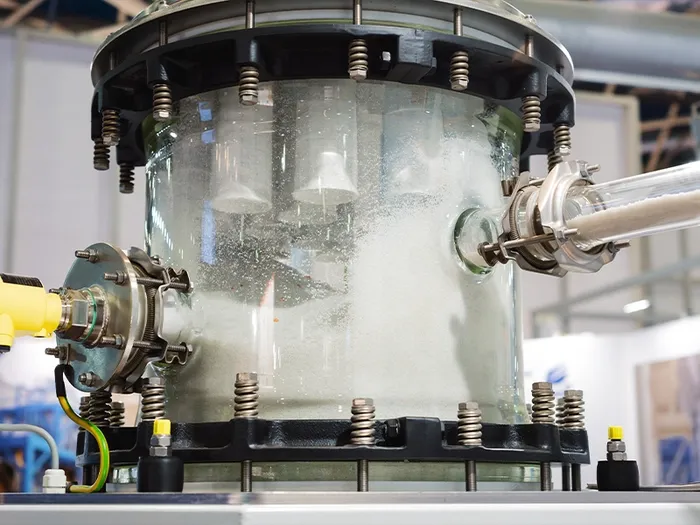

Central to the operation of fuel cells is the controlled delivery of reactants to the cell's anodes and cathodes. Our industry-leading blowers are essential for this, providing a range of functionalities to enhance your fuel cell system designs. From air injection blowers that ensure an optimal mix for electricity generation, to fuel gas injection blowers that deliver the necessary gases, and anode gas recirculation blowers that improve system efficiency – our products cover all your needs.

With our comprehensive suite of blowers and compressors, you can optimize every aspect of your fuel cell's operation, whether it's refining the manufacturing process or maximizing the energy output of the system itself.