What is an oil lubricated vacuum pump?

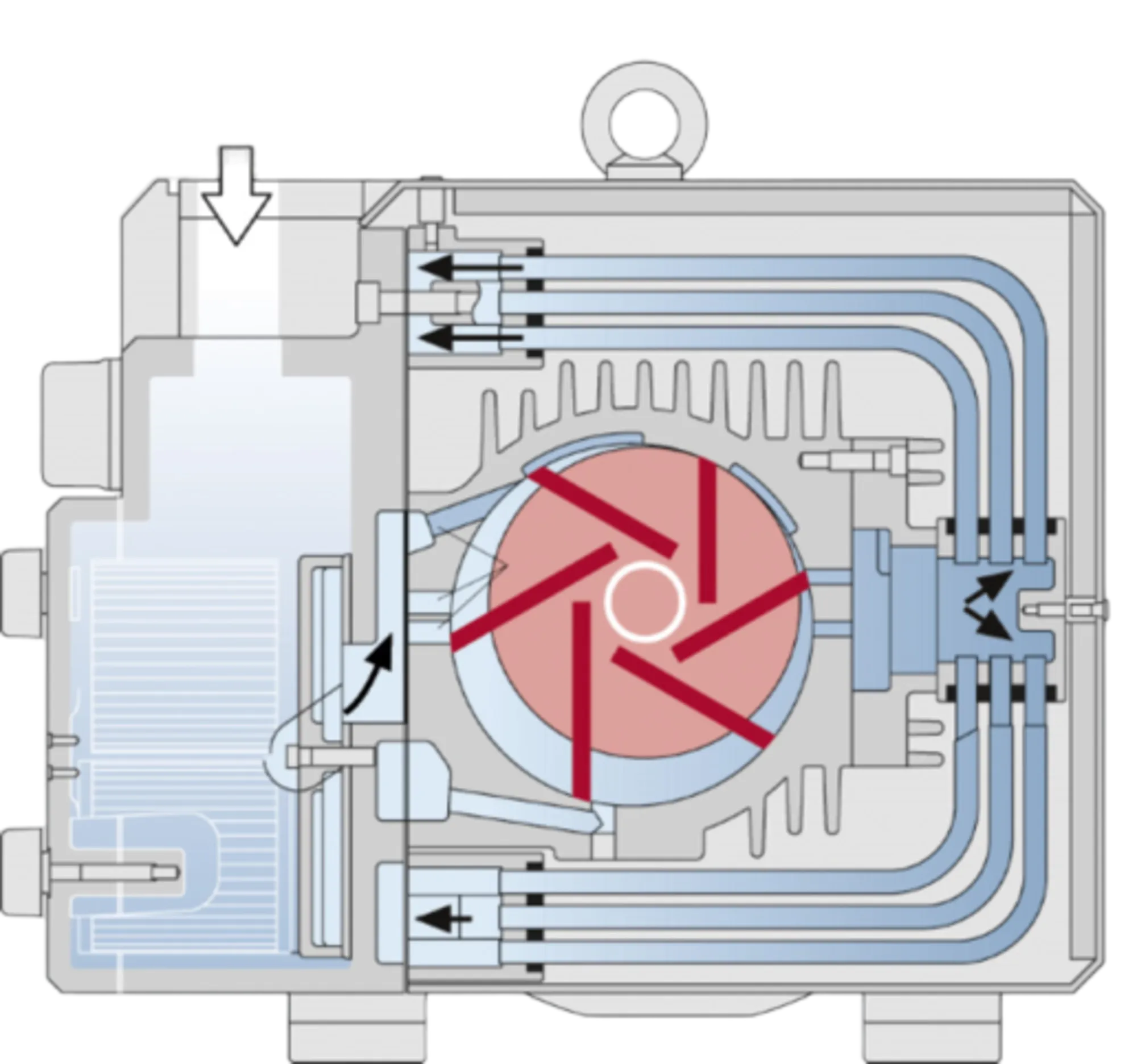

Also known as oil-flooded or oil-sealed vacuum pumps, these systems use oil to create a reliable seal, enabling deeper vacuum levels to be achieved.

But the oil does much more than seal. It lubricates key internal components like vanes, rotor, housing, and bearings, reducing wear and extending service life. It also helps lower operating temperatures by minimizing friction and protecting against corrosion.

Crucially, the oil carries away the heat of compression, allowing the compression chamber to run cooler and more efficiently, keeping performance high and impurities low.

Oil-Lubricated Rotary Vane Pumps

Elmo Rietschle’s oil-lubricated rotary vane pumps are engineered to deliver exceptional vacuum performance, reliability, and long service life. The innovative design uses oil as both a lubricant and sealing agent, ensuring smooth operation, reduced wear, and extended maintenance intervals.

The pumps feature a cylindrical housing with an eccentrically positioned rotor. Rotor vanes slide in and out of slots, maintaining contact with the cylinder walls to create cells of varying volume during rotation. This constant change in cell volume generates suction and compression cycles that produce vacuum efficiently.

The de-oiling chamber ensures that the oil-gas mixture is filtered, separating oil particles from the gas for clean operation. Larger oil droplets are collected in an oil sludge recipient, while finer particles are separated through filter elements and reintroduced into the pump’s oil circuit for optimal performance.